When a network of 10 Upper Midwest hospitals came together in 2019, it became clear pretty quickly to the organization’s Manager for Transfusion Services there was a lack of consistent processes across the blood banks. That’s why streamlining how blood products were moved around the hospital and transported to other sites was a priority from the outset. Standardizing packout processes was essential to making that happen – and the place to start was with the coolers.

The Challenge: Network-wide Standardization

When they came together, each of the 10 hospital blood banks had different types and sizes of recreational coolers and its own way of doing things. Some made their own ice bags, which often meant ice behaved differently from packout to packout. Others were using cold packs, but they ranged in size and didn’t have the same level of firmness. It could be wet ice just out of the freezer or hard ice that had been sitting in the deep freezer for a month or more. This makes a difference because it could require extra padding – a process that also wasn’t consistent. Where some might use one layer of padding, others might use two, and others still might use bubble wrap.

Since the entire process wasn’t standard, the time it took to assemble each packout also varied. Plus, because the coolers were not designed specifically for blood transport, they could be bulky and cumbersome to transport.

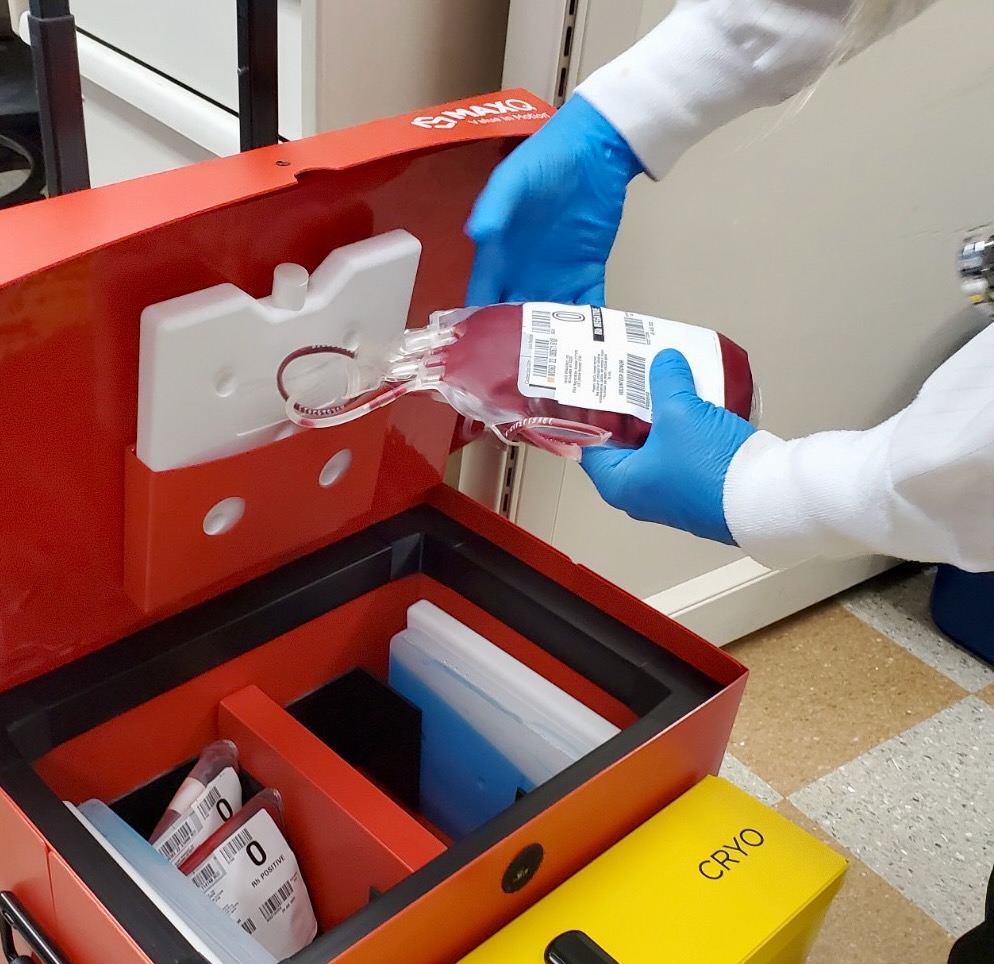

Solution: MaxPlus MTP Cooler®

As the Transfusion Services staff began researching solutions, they found that one of the blood banks was using the MaxPlus MTP Coolers® for their Massive Transfusion Protocol (MTP) protocol and really liked them. A Lead Medical Technologist at another network blood bank also had experience using the coolers in a previous role and had been responsible for validating them. Based on this collective feedback, the hospital system decided to implement the MaxPlus MTP Coolers across their entire network.

MaxPlus MTP Cooler At-a-Glance

- Separate areas for RBCs, plasma and platelets in a single integrated cooler

- Qualified for up to 12 hours, ready for blood bank validation

- No bench-time or special handling, simplifying packouts and improving efficiency

- Retractable handle and wheels for easy transport

- Durable, easy to clean and disinfect for a long life

- AABB Standards-Compliant

Result: Increased Efficiency

Today, each of the 10 hospital blood banks have implemented MaxPlus MTP Coolers. With this, they have successfully developed a standardized method of packing coolers so everybody can do it exactly the same way every time. Technicians simply place freezer or refrigerator packs where indicated and drop each blood product into its individual spot. The box is clearly labeled – so it’s easy to see where RBCs, plasma and room temperature blood products go.

Busier blood banks use the coolers daily, so they are well-versed in packing them out. For some of the smaller operations that don’t use them as frequently, the team created simple packout instructions that are adhered to the lid as a reminder. The simplicity of the packout also makes training easy. Clear and straightforward training takes 5-10 minutes to demonstrate the packout and explain the site’s policy.

Busier blood banks use the coolers daily, so they are well-versed in packing them out. For some of the smaller operations that don’t use them as frequently, the team created simple packout instructions that are adhered to the lid as a reminder. The simplicity of the packout also makes training easy. Clear and straightforward training takes 5-10 minutes to demonstrate the packout and explain the site’s policy.

The MaxPlus MTP Cooler arrives from MaxQ pre-qualified along with a validation guide. To validate the coolers for their purposes, Transfusion Services staff simply devised a timeline and checked coolers every 30 minutes for about 12 hours. Sometimes this included a shift change and the next person might forget to unpack the cooler. When checked, however, even as much as 16 hours or more later, the cooler maintained temperatures within the 1 – 10o C specifications. That’s how they knew the coolers could last so much longer than 12 hours, giving them added confidence.

The fact that coolers are validated internally for 12 hours saves the staff a lot of time. In the past, they would have to call coolers back every four hours – which meant packing out and transporting a new cooler (or three if RBCs, plasma and platelets were required). Now, when they send up a fresh cooler within the 12-hour time frame, they can just have nurses transfer the blood product in the original cooler to the new one because they know it’s stayed in temperature.

Having those tight timeframes on the old processes and coolers also increased the risk of blood loss. These losses are particularly devastating given today’s fragile blood supply, going beyond the financial costs and the importance of respect for blood donors. While the hospital system didn’t historically have a lot of wastage, when it did happen it was almost always due to improper handling. Their outlook? If MaxPlus MTP Coolers can bring wastage down to almost zero – saving just two units of blood, say – they’ve paid for themselves.

“Everything we do is for the patients. It’s so worth having the confidence in this system. Anyone can pack it out. Anybody can handle it. And knowing that the blood product someone takes the time to donate will be protected is priceless.”

Lead Medical Technologist

In the end, the blood banks are far more efficient. That’s because in the past they used to have to pack multiple coolers for different types of blood products. So if they were packing six red cells, six fresh frozen plasma and two platelets, that meant three separate coolers. Now they can use just one cooler, which saves a lot of time – immeasurably valuable in an emergency situation. For example, since the MaxPlus MTP Coolers can be packed out in 30 seconds for immediate delivery to a trauma, blood is getting where it’s needed – to patients – in record time.

That also means only one cooler to pick up. The MaxPlus MTP Cooler is also on wheels, so when they have someone coming down to pick up a cooler they don’t have to waste time looking for carts to transport multiple coolers as they did before. It’s just much easier to transport blood either within the hospital or from location to location.